Step change thermal management of RF devices using CVD diamond

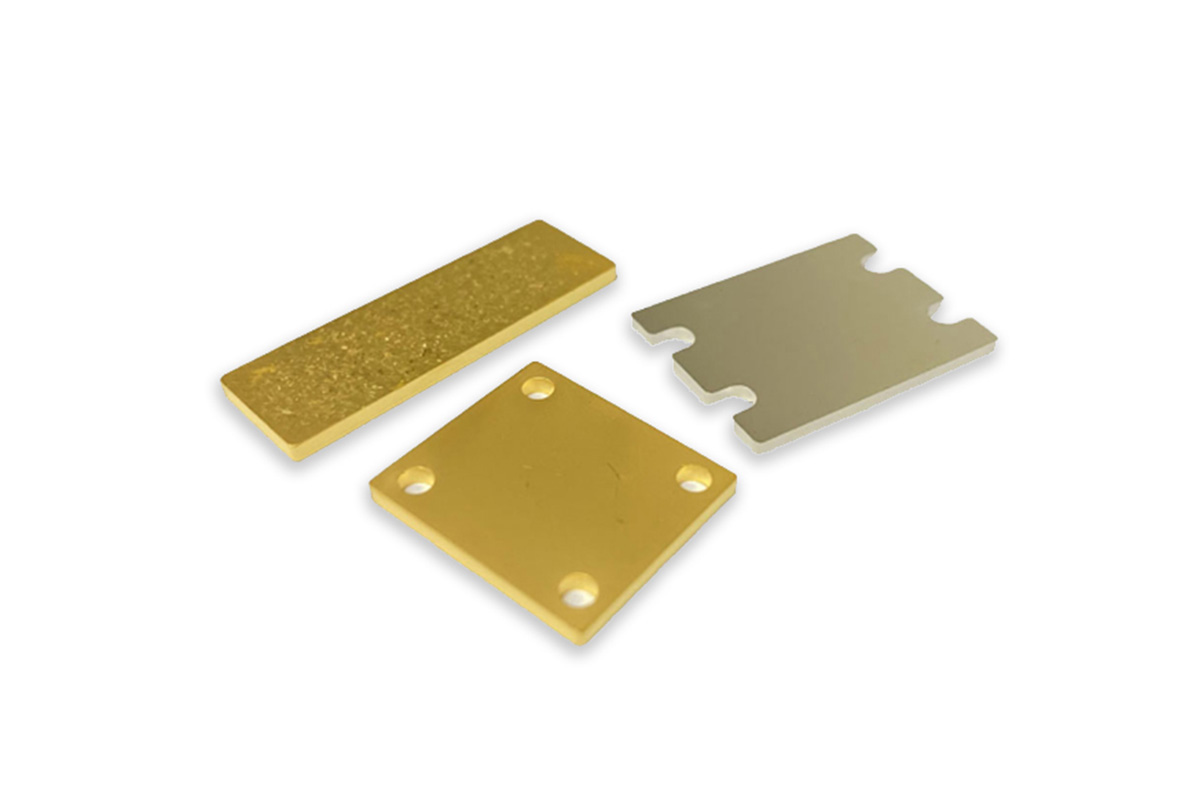

Thermal conductivity can be engineered to suit the application, but it is necessary to consider the system as a whole in order to achieve maximum benefits.

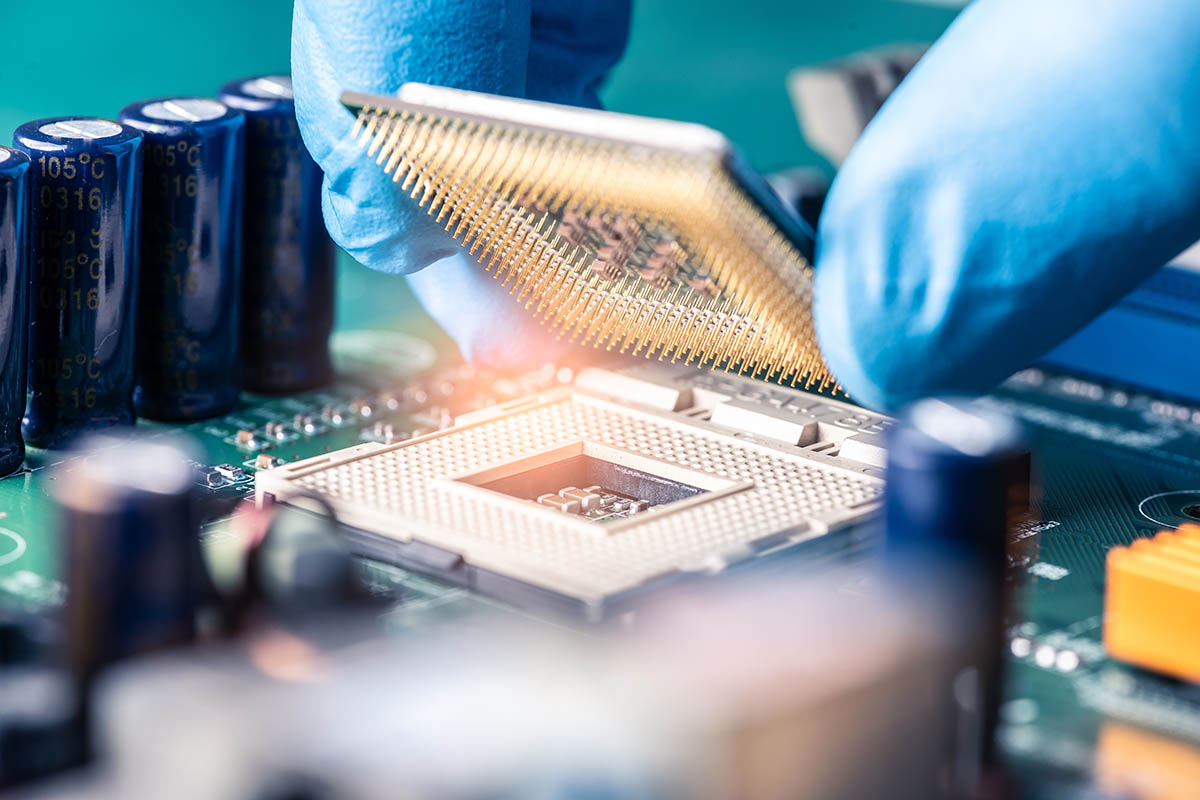

For active devices CVD diamond heat spreaders enable:

- Higher power operation for a given maximum operating temperature

- Reduced peak temperatures (~25%) for a given power

RF resistors using CVD diamond substrates can operate at higher frequencies and powers before parasitic effects lead to signal distortion (>100w & > 10 GHz). | Read more